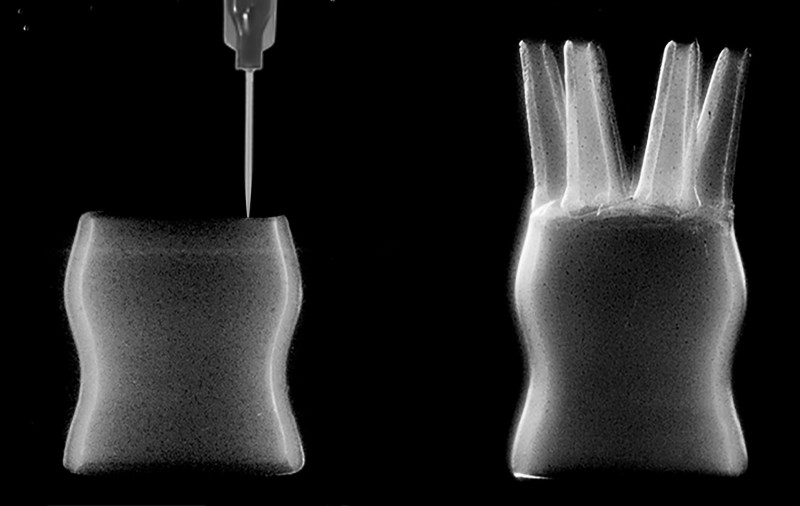

University of Florida (UF) researchers have developed a method for 3D printing soft-silicone medical implants that are stronger, quicker, less expensive, more flexible, and more comfortable than the implants currently available. That should be good news for the millions of people every year who need medical devices implanted.

Currently, such devices — such as ports for draining bodily fluids (cerebral spinal fluid in hydrocephalus, for example), implantable bands, balloons, soft catheters, slings and meshes — are mass produced and made through molding processes. To create customized parts for individual patients with molding would be very expensive and could take days or weeks for each job.

New 3D printing method